Indledning

This manual provides detailed instructions for the safe and efficient operation, setup, and maintenance of your KATOOL ME-620T Wheel Balancer. Please read this manual thoroughly before operating the machine to ensure proper usage and to prevent damage or injury. The KATOOL ME-620T is designed for precise balancing of car wheels, featuring robust construction and advanced balancing capabilities.

Sikkerhedsoplysninger

Overhold altid følgende sikkerhedsforanstaltninger:

- Ensure the machine is placed on a level, stable surface.

- Tilslut maskinen til en jordet stikkontakt med den korrekte lydstyrke.tage (110V/1PH).

- Hold hænder og tøj væk fra bevægelige dele under drift.

- Brug passende personlige værnemidler (PPE), såsom sikkerhedsbriller.

- Brug ikke maskinen, hvis nogen af delene er beskadigede eller mangler.

- Refer to the warning labels on the machine for additional safety instructions.

Opsætning og installation

Proper setup is crucial for accurate balancing and safe operation.

1. Udpakning og placering

Carefully unpack all components. Position the wheel balancer on a firm, level floor. The machine's base is designed for stability, with an extension point to prevent tipping when handling larger tires.

Billede 1: The KATOOL ME-620T Wheel Balancer shown with its included accessories, including the wheel clamp, measuring caliper, and various cones. The main unit is blue with a digital display and control panel.

Billede 2: Et nærbillede view of the wheel balancer's base, highlighting the extension point designed to enhance stability and prevent the machine from tipping over when balancing larger or heavier wheels.

2. Strømtilslutning

Connect the power cord to a 110V/1PH grounded electrical outlet. Ensure the power switch is in the OFF position before connecting.

3. Shaft and Cone Installation

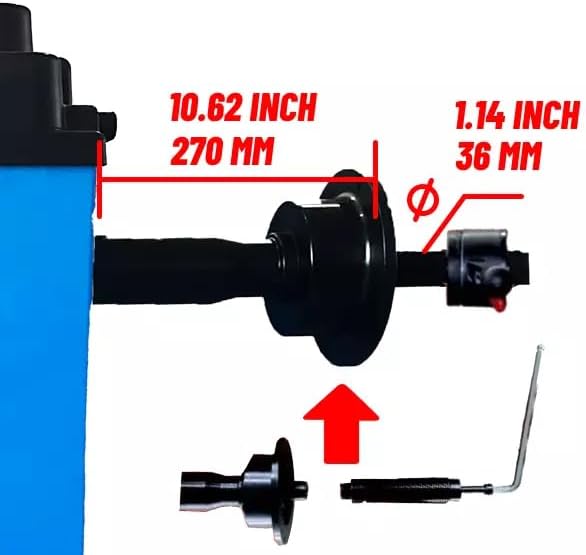

The machine features a φ36mm shaft. Select the appropriate cone size for the wheel being balanced. The shaft is designed for high strength due to quenching treatment.

Billede 3: This image illustrates the dimensions of the wheel balancer's shaft, showing a diameter of 1.14 inches (36 mm) and a length of 10.62 inches (270 mm). This detail is important for selecting the correct wheel adapters.

Billede 4: Et nærbillede view demonstrating the "reverse fitting" method for mounting a wheel onto the balancer's shaft. This technique is used for specific wheel types to ensure a secure and accurate fit.

Betjeningsvejledning

1. Mounting the Wheel

- Clean the wheel and rim thoroughly.

- Select the appropriate mounting cone for the wheel's center bore.

- Mount the wheel securely onto the balancer shaft, ensuring it is centered and tightened with the quick-release nut.

2. Inputting Wheel Parameters

Use the control panel to input the wheel's dimensions. The machine supports unit selection (Ounce/Gram, MM/Inch).

- Fælg diameter: 10" til 24" (254 mm til 610 mm)

- Fælgbredde: 1.5" til 20" (38 mm til 508 mm)

- Use the measuring caliper to accurately determine the rim width and distance from the machine.

Billede 5: En detaljeret view of the KATOOL ME-620T's control panel and digital display. The display shows "INNER VALUE" and "OUTER VALUE" for balance readings, along with graphical representations of the wheel. The control panel features buttons for various balance modes (A, B, C, D, F, ALU), unit selection (MM/INCH), and operation (START, STOP).

Billede 6: A close-up showing the use of a measuring caliper to determine the distance from the wheel to the balancer. This measurement is critical for accurate data input into the machine.

3. Selecting Balance Mode

The ME-620T offers various balance modes to suit different rim types. Select the appropriate mode (e.g., ALU for alloy wheels) using the control panel buttons (A, B, C, D, F, ALU).

4. Starting the Balancing Cycle

Once parameters are set, press the "START" button. The wheel will rotate at 210rpm, and the balancing process will typically take 8-10 seconds. The display will show the required weight and its placement.

5. Applying Balance Weights

Apply the indicated balance weights to the rim at the positions shown on the display. Re-spin the wheel to verify the balance. The balancing precision is 1g.

Opretholdelse

- Rensning: Regularly clean the machine, especially the shaft and sensor areas, to prevent debris from affecting accuracy.

- Kalibrering: The ME-620T has a built-in self-calibration program (double-side calibration). Perform calibration periodically or if accuracy issues arise.

- Inspektion: Periodically inspect all cables, connections, and mechanical parts for wear or damage.

- Motor: The pure copper winding motor is designed for fast heat dissipation and long life. Ensure adequate ventilation around the machine.

- Computerkort: The advanced welding technology of the computer board makes it moisture-proof, dust-proof, and anti-static, contributing to a longer lifespan.

Fejlfinding

The ME-620T includes a built-in fault diagnosis program. If an issue occurs, consult the display for error codes or messages.

- Upræcise læsninger:

- Ensure wheel is clean and properly mounted.

- Verify correct wheel parameters have been entered.

- Perform self-calibration.

- Maskinen starter ikke:

- Kontroller strømtilslutning og afbryder.

- Ensure safety guards are in place (if applicable).

- Overdreven vibration:

- Confirm the machine is on a stable, level surface.

- Tjek for løse komponenter eller beskadigede dele.

For issues not resolved by these steps, contact KATOOL customer support.

Specifikationer

| Feature | Specifikation |

|---|---|

| Model | ME-620T |

| Max Wheel Weight | 65 kg (144 lbs) |

| Motorkraft | 250 W |

| Voltage | 110 V / 1 PH |

| Balancing Precision | 1 g |

| Rotationshastighed | 210 rpm |

| Fælg diameter | 10" – 24" (254 mm – 610 mm) |

| Fælgbredde | 1.5" – 20" (38 mm – 508 mm) |

| Balancing Time | 8-10 sekunder |

| Støjniveau | < 70 dB(A) |

| Nettovægt (NW) | 105 kg |

| Outer Dimensions (L×W×H) | 1200 × 1400 × 1760 mm |

| Arbejdstemperatur | 0 – 50 ℃ |

| Shaft Thread Diameter | φ36 mm |

Garanti og support

For warranty information, please refer to the documentation provided at the time of purchase or contact KATOOL customer service directly. Keep your purchase receipt as proof of purchase.

For technical support, parts, or service inquiries, please contact KATOOL through their official channels. Ensure you have your model number (ME-620T) and serial number ready when contacting support.