1. Introduktion

The Inficon Vortex Dual is a high-performance refrigerant recovery machine designed for efficiency and durability in HVAC, refrigeration, and automotive applications. It offers industry-leading recovery rates and is built to withstand demanding professional environments.

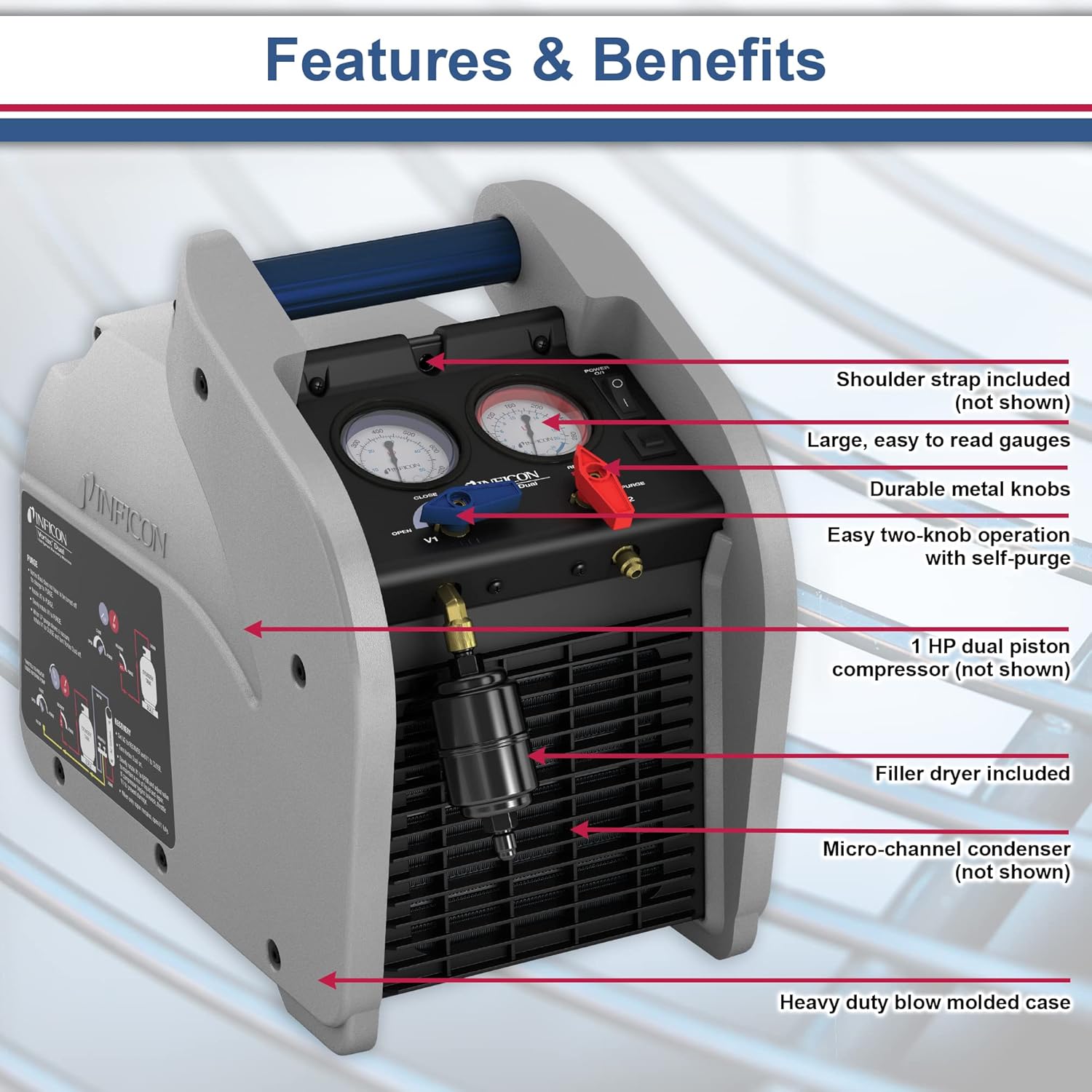

Figur 1: Forside view of the Inficon Vortex Dual Refrigerant Recovery Machine.

2. Nøglefunktioner

The Vortex Dual is engineered with advanced components to ensure reliable and fast refrigerant recovery:

- Kraftig kompressor: Equipped with a 1 HP dual piston compressor for industry-leading recovery rates.

- Efficient Condenser: Features a microchannel condenser for exceptional heat exchange, especially in high temperatures.

- Brugervenlig betjening: Designed with two-valve operation and a self-purge function for ease of use.

- Clear Readouts: Large, easy-to-read gauges provide clear pressure indications.

- Robust konstruktion: Built with durable metal knobs and housed in a heavy-duty blow-molded case for enhanced durability.

- Serviceable Design: Fully serviceable for long-term reliability.

Figure 2: Diagram highlighting key features of the Vortex Dual machine.

3. Hvad er inkluderet

Upon unboxing your Inficon Vortex Dual, you should find the following components:

- Inficon Vortex Dual Refrigerant Recovery Machine

- Skulderrem

- Filter/tørretumbler

- Detachable Power Cord (6-foot)

Figure 3: All items included with the Inficon Vortex Dual.

4. Opsætning

Before operating the Vortex Dual, ensure proper setup for safe and efficient use:

- Placering: Place the recovery machine on a stable, level surface in a well-ventilated area.

- Strømtilslutning: Connect the detachable power cord to the machine's power inlet and then to a suitable electrical outlet (refer to specifications for voltage krav).

- Filter/Dryer Installation: Attach the provided filter/dryer to the appropriate port on the machine. This helps protect the unit from contaminants.

- Slangeforbindelser: Connect your refrigerant hoses to the machine's input and output ports, and to the system being serviced and the recovery tank, respectively. Ensure all connections are tight to prevent leaks.

- Gauge Check: Verify that the gauges are in good condition and reading correctly before starting any operation.

5. Betjeningsvejledning

The Inficon Vortex Dual is designed for straightforward operation. Always refer to the full user manual for detailed procedures and safety warnings.

5.1 Compatible Refrigerants

The Vortex Dual is compatible with a wide range of refrigerants, including AHRI Class III, IV, and V refrigerants such as R-22, R-410A, and R-134A.

Figure 4: Compatible refrigerants for the Vortex Dual.

5.2 General Recovery Process

While specific steps vary by refrigerant and system, the general process involves:

- Tilslut slanger: Ensure all hoses are securely connected between the system, the recovery machine, and the recovery tank.

- Åbne ventiler: Open the necessary valves on the system, machine (V1 and V2), and recovery tank to allow refrigerant flow.

- Tænd: Turn on the Vortex Dual using the power switch.

- Monitormålere: Continuously monitor the machine's gauges to track pressure and ensure proper recovery.

- Self-Purge Function: Utilize the self-purge function to clear residual refrigerant from the machine's internal components, preventing cross-contamination between different refrigerants.

- Fuldstændig genopretning: Continue operation until the system pressure reaches the desired vacuum level, indicating complete refrigerant recovery.

Video 1: Official product video demonstrating the Inficon Vortex Dual Refrigerant Recovery Machine in operation, highlighting its features and capabilities for HVAC, refrigeration, and automotive applications. This video provides a visual guide to the machine's use and benefits.

6. Vedligeholdelse

Regular maintenance ensures the longevity and optimal performance of your Vortex Dual:

- Filter/Dryer Replacement: Periodically inspect and replace the filter/dryer as needed, especially after recovering contaminated refrigerant or when recovery rates decrease.

- Rensning: Keep the exterior of the machine clean. Ensure the condenser fins are free of dust and debris to maintain efficient heat exchange.

- Slangeinspektion: Regularly check hoses for wear, cracks, or leaks. Replace damaged hoses immediately.

- Opbevaring: Opbevar maskinen et tørt og rent sted, når den ikke er i brug.

7. Fejlfinding

This section covers common issues and their potential solutions. For comprehensive troubleshooting, consult the full user manual.

| Problem | Mulig årsag | Løsning |

|---|---|---|

| Slow Recovery Rate | Clogged filter/dryer; high ambient temperature; kinked hoses. | Replace filter/dryer; ensure adequate ventilation; check hose routing. |

| Maskine starter ikke | No power; tripped circuit breaker; faulty power cord. | Check power supply; reset breaker; inspect/replace power cord. |

| Leaks Detected | Loose connections; damaged hoses or O-rings. | Tighten all connections; replace worn components. |

8. Specifikationer

| Attribut | Detalje |

|---|---|

| Produktdimensioner | 16.7 x 9.2 x 14.2 tommer |

| Vægt | 29.75 pund |

| Varemodelnummer | 714-202-G1 |

| Fabrikant | Inficon |

| Oprindelsesland | USA |

| Kompressor | 1 HK dobbeltstempel |

| Kondensatortype | Mikrokanal |

| Kompatible kølemidler | AHRI Class III, IV, V (e.g., R-22, R-410A, R-134A) |

9. Garanti og support

The Inficon Vortex Dual comes with an industry-leading Three-Year Over-the-Counter Warranty, providing confidence in your purchase.

For technical assistance, troubleshooting, or warranty claims, please contact Inficon US Technician Support via Email and Phone. Refer to the official Inficon webhjemmeside for aktuelle kontaktoplysninger.

10. Yderligere ressourcer

For a complete and detailed guide, including comprehensive safety information, detailed operating procedures, and advanced troubleshooting, please download the official User Manual: