1. Introduktion

The ARCCAPTAIN TIG Welder 200A is a versatile and powerful 2-in-1 welding machine, offering both High Frequency TIG and Stick (MMA) welding capabilities. Designed for both 110V and 220V dual voltage operation, it provides up to 200 amps, ensuring precise welds for stainless and mild steel. Featuring an advanced MCU and IGBT Inverter technology digital control system, it delivers flawless welds with minimal spatter. Key functions include Post Gas, Down-slope, and 2T/4T, all easily managed via a large LED digital display. Its lightweight and compact design, coupled with a fan-on-demand cooling system and comprehensive safety features (VRD, over current/voltage/load/heating protection), make it an ideal choice for various welding tasks.

Figure 1: ARCCAPTAIN TIG Welder 200A and included accessories.

2. Sikkerhedsforanstaltninger

Prioritér altid sikkerheden ved brug af svejseudstyr. Manglende overholdelse af sikkerhedsretningslinjerne kan resultere i alvorlig personskade eller død.

- Elektrisk stød: Welding current can cause fatal electric shock. Always wear dry, insulated gloves and clothing. Ensure proper grounding of the welding machine and workpiece. Never touch live electrical parts.

- Røg og gasser: Svejserøg og -gasser kan være sundhedsfarlige. Arbejd i et godt ventileret område. Brug lokal udsugning eller åndedrætsværn, hvis ventilationen er dårlig.

- Bue stråler: Arc rays can injure eyes and burn skin. Always wear a welding helmet with a proper shade filter. Wear protective clothing (long sleeves, pants, and welding gloves) to protect exposed skin.

- Brand og eksplosion: Welding can cause fire or explosion. Keep flammable materials away from the welding area. Have a fire extinguisher readily available. Do not weld on containers that have held flammable materials.

- Forbrændinger: Hot metal and sparks can cause burns. Wear protective clothing and gloves. Allow welded materials to cool before handling.

- Støj: Some welding operations can produce noise that may damage hearing. Wear ear protection.

Figure 2: The ARCCAPTAIN TIG200 features multiple safety protections including VRD, over current/voltage/load/heating protection, and IP21S water rating.

3. Komponenter og tilbehør

3.1 Inkluderet tilbehør:

- ARCCAPTAIN 200 Amp TIG-svejser

- 13ft TIG Torch

- 10 fod jordklodsamp

- 10 fods elektrodeholder

- Conversion adapter (for 110V power)

- 8ft Argon Gas Hose (with connector)

- Børste og hammer

- Wolfram elektrode

- Skulderrem

Figure 3: All accessories included with your ARCCAPTAIN TIG Welder 200A.

3.2 Welder Components:

Familiarize yourself with the main components of the ARCCAPTAIN TIG200 welder:

- Knap til svejsetilstand: Selects between MMA (Stick) and TIG (2T/4T) modes.

- Preferences Selection: Adjusts parameters like Down-slope and Post Gas.

- Kontroltilstand: Switches between Panel and Remote control (for foot pedal).

- Adjustable Knob: Used to set amperage and other numerical parameters.

- LED digitalt display: Shows current settings and welding parameters.

- Positive Welding Terminal (+): Connects to the electrode holder for Stick welding or the ground clamp for TIG welding.

- Negative Welding Terminal (-): Connects to the ground clamp for Stick welding or the TIG torch for TIG welding.

- Gas Outlet: Connects to the argon gas hose.

- TIG Torch Connector: Connects the TIG torch.

- Luftventiler: Ensures proper cooling of the internal components.

- Afbryderen: Tænder/slukker maskinen.

- Strømkabel: Connects the machine to the power source.

- Køleventilator: Activates only when needed to reduce noise and save energy.

- Gasindtag: Connects to the argon regulator and gas cylinder.

Figur 4: Foran og bagpå view of the ARCCAPTAIN TIG Welder 200A with labeled components.

4. Opsætning

4.1 Strømtilslutning:

- The ARCCAPTAIN TIG200 supports both 110V and 220V input.

- For 220V, connect the main power cable directly to a compatible 220V outlet.

- For 110V, use the provided conversion adapter to connect the main power cable to a 110V outlet.

- Ensure the power source meets the machine's requirements (refer to specifications).

4.2 Gas Connection (TIG Welding):

- Connect the argon gas hose to the Gas Inlet on the rear of the machine and to your argon gas cylinder via the regulator.

- Sørg for, at alle forbindelser er sikre for at forhindre gaslækager.

4.3 Connecting Welding Cables:

The connection method depends on the welding mode:

- TIG-tilstand: Connect the TIG torch to the TIG Torch Connector. Connect the ground clamp cable to the Positive Welding Terminal (+).

- Stick Mode: Connect the electrode holder cable to the Positive Welding Terminal (+). Connect the ground clamp cable to the Negative Welding Terminal (-).

Figure 5: Proper cable connections for Stick and TIG welding modes.

4.4 Foot Pedal Connection (Optional):

- If using an optional foot pedal, connect it to the 5-pin foot pedal interface on the welder.

- Switch the Control Mode to 'Remote' on the display panel to enable foot pedal control.

Figure 6: The welder features a 5-pin foot pedal interface for precise amperage kontrol.

5. Betjeningsvejledning

5.1 Tænd:

- Sørg for, at alle forbindelser er sikre.

- Flip the Power Switch to the 'ON' position. The LED display will illuminate.

- The cooling fan will run briefly during startup and then activate only when necessary during operation.

5.2 Selecting Welding Mode:

- Press the 'Welding Mode' button to toggle between MMA (Stick) and TIG (2T/4T) modes.

Figure 7: The ARCCAPTAIN TIG200 supports both High Frequency TIG and MMA (Stick) welding.

5.3 Adjusting Parameters:

- Use the 'Adjustable Knob' to set the desired ampslette.

- In TIG mode, you can adjust 'Post Gas' time (1-10s) and 'Down-slope' time (0-10s) via the 'Preferences' button.

Figure 8: Post Gas protects the weld and torch, while Down-slope ensures a smooth current decay.

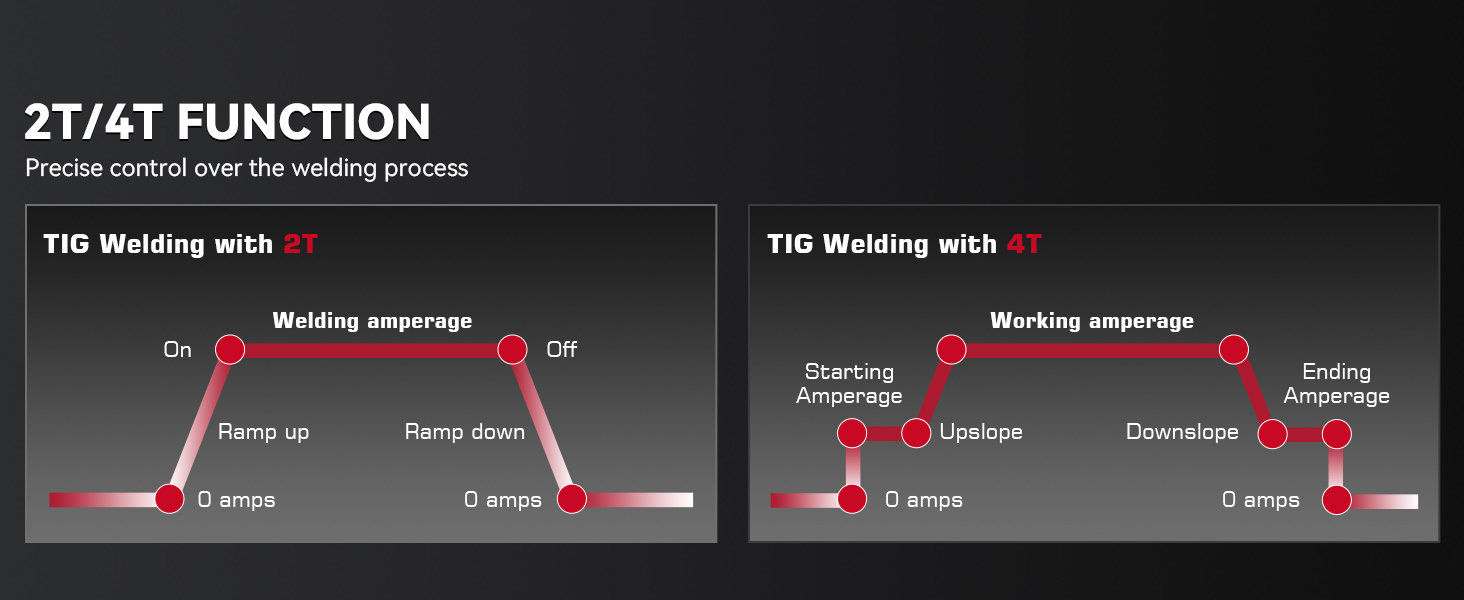

5.4 2T/4T Function (TIG Mode):

- 2T (To-berøringsfunktion): Press and hold the torch trigger to start the arc and weld. Release the trigger to stop. Ideal for short welds.

- 4T (fire-berøringsfunktion): Press and release the trigger to start the arc. The arc will remain active until the trigger is pressed and released again. Suitable for long welds, reducing hand fatigue.

Figure 9: Understanding 2T and 4T functions for precise welding control.

5.5 Welding Different Materials:

The ARCCAPTAIN TIG200 is suitable for various metals including Carbon Steel, Stainless Steel, and Copper. It can handle material thicknesses from 0.02 inches (0.5mm) to 0.4 inches (10mm).

Figure 10: The welder is suitable for Carbon Steel, Stainless Steel, Copper, Sheet Metal, Square Pipe, and Round Tube.

Figure 11: The ARCCAPTAIN TIG200 can weld materials from 0.02 inches (0.5mm) to 0.4 inches (10mm) thick.

5.6 Officiel produktvideo:

Video 1: Official ARCCAPTAIN High Frequency TIG Welder 200A (with MMA) product overview.

6. Vedligeholdelse

- Rensning: Regularly clean the machine's exterior with a soft, dry cloth. Ensure air vents are free from dust and debris to maintain proper airflow.

- Ventilatorbetjening: The cooling fan operates on demand. Do not block the air vents.

- Kabelinspektion: Periodically inspect welding cables, torch, and ground clamp for tegn på skader, flosning eller løse forbindelser. Udskift beskadigede komponenter med det samme.

- Opbevaring: Opbevar svejsemaskinen et tørt og rent miljø væk fra direkte sollys og ekstreme temperaturer.

Figure 12: The ARCCAPTAIN TIG200 undergoes rigorous testing for durability, including vibration, drop, waterproof, and metal dust tests.

7. Fejlfinding

If you encounter issues with your ARCCAPTAIN TIG Welder 200A, refer to the following common problems and solutions:

- Ingen strøm: Check the power cable connection, ensure the power switch is on, and verify the power outlet is functioning. For 110V, ensure the adapter is correctly used.

- Ingen bue: Ensure proper grounding of the workpiece. Check all cable connections (torch, ground clamp, electrode holder). Verify correct welding mode selection.

- Dårlig svejsekvalitet: Tilpasse amperage settings according to material thickness (refer to setup guide). Ensure proper gas flow (for TIG). Check for clean workpiece and correct electrode/filler rod.

- Overophedning: The machine has built-in overheating protection. If it shuts down due to overheating, allow it to cool down. Ensure proper ventilation and clear air vents.

- Ventilator kører ikke: The fan operates on demand. It will only run when the machine requires cooling. This is normal operation.

For more detailed troubleshooting or issues not listed here, please contact ARCCAPTAIN customer support.

8. Specifikationer

| Feature | Værdi |

|---|---|

| Mærke | ARCCAPTAIN |

| Modelnummer | ARCCAPTAIN TIG200 |

| Varenummer | TIG200 |

| Varens vægt | 20.8 pund |

| Pakkedimensioner | 18.25 x 15 x 7.25 tommer |

| Farve | Rød |

| Stil | TIG200 |

| Mønster | TIG200 |

| Batterier inkluderet? | Ingen |

| Batterier påkrævet? | Ingen |

| Dato først tilgængelig | 2. juli 2022 |

Figure 13: Detailed electrical specifications for the ARCCAPTAIN TIG Welder 200A.

Figure 14: TIG200 Set-Up Guide providing recommended amperage, tungsten, filler metal, and gas settings for steel and stainless steel.

9. Garanti og support

ARCCAPTAIN offers a 3-year quality service for this product. For any questions, technical assistance, or warranty claims, please contact ARCCAPTAIN customer support through their official channels. Refer to the product packaging or ARCCAPTAIN's official webhjemmeside for de mest opdaterede kontaktoplysninger.