Indledning

This instruction manual provides detailed guidance for the installation and maintenance of your ICT Billet LS Truck Power Steering Pump and Alternator Relocation Bracket Kit (Model 551396LS0-3). This kit is designed to relocate the power steering pump and alternator on various LS truck engines, providing improved clearance and accessory drive solutions for custom applications. Please read all instructions carefully before beginning installation.

Sikkerhedsoplysninger

- Always disconnect the vehicle's battery before performing any work on the engine or electrical system.

- Brug passende personlige værnemidler, herunder sikkerhedsbriller og handsker, under installationen.

- Ensure the vehicle is securely supported on jack stands or a lift before working underneath it.

- Allow the engine to cool completely before handling components.

- If you are unsure about any step of the installation process, consult a qualified automotive professional.

Pakkens indhold

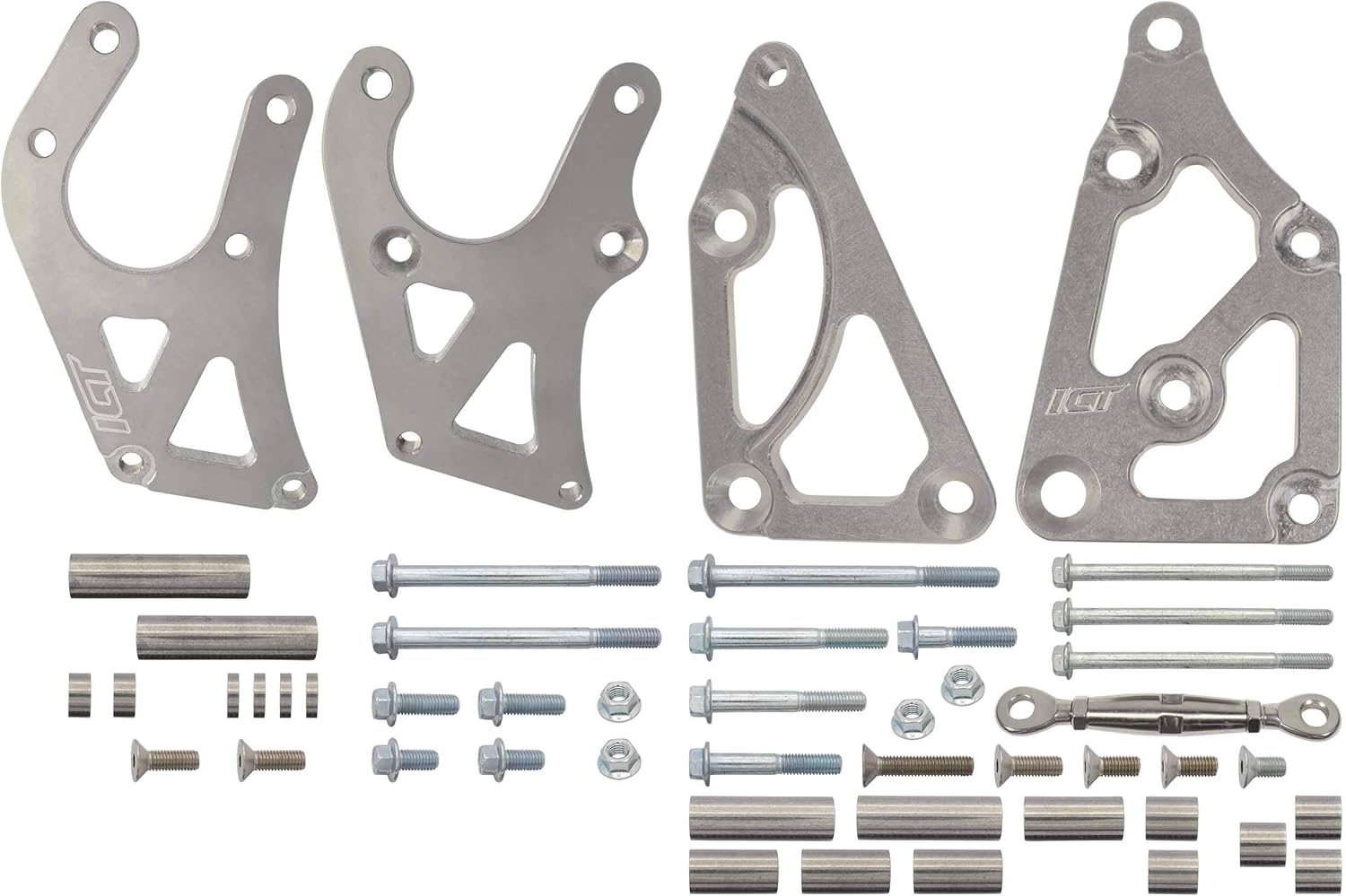

Verify that all components listed below are present in your kit before beginning installation:

Image: All components included in the ICT Billet LS Truck Power Steering Pump and Alternator Relocation Bracket Kit, laid out for inspection. This includes various aluminum brackets, bolts, nuts, spacers, and a turnbuckle.

- Alternator Relocation Bracket (Main)

- Power Steering Pump Relocation Bracket

- Turnbuckle Adjuster

- Mounting Hardware (various bolts, nuts, and spacers)

Opsætning og installation

Overvejelser før installation

Before installing the bracket kit, ensure compatibility with your specific LS engine setup. This kit is designed for LS truck engines (e.g., 5.3L, 6.0L) and requires specific crank pulley spacing and alternator types for optimal fitment.

Image: A detailed guide illustrating different LS crank pulley spacing types (Corvette, Camaro/GTO, Truck/SUV) and their corresponding part numbers. This is crucial for ensuring proper belt alignment.

- Crank Pulley Spacing: This kit is designed for LS engines utilizing the truck/SUV crank pulley spacing (Part # ending in -3). Refer to the LS Crank Spacing Guide image to confirm your engine's setup. Incorrect spacing will lead to belt misalignment.

- Vandpumpe: The kit is compatible with both truck-style and Camaro-style water pumps. Shims are provided to accommodate the differences.

- Generator type: This kit is optimized for the smaller 105 amp GM alternators commonly found on light-duty LS trucks. Larger 160 amp alternators may cause clearance issues with the water pump outlet, requiring a shorter belt or a Camaro-style water pump.

- Bæltelængde: The required belt length will vary based on your specific setup (water pump, alternator, and crank pulley). It is recommended to measure the required belt length after all components are mounted. A common starting point for truck spacing is a 6-rib belt around 67-68 inches (e.g., 6K680).

Installationstrin

Følg disse trin omhyggeligt for korrekt installation:

- Forbered motor: Ensure the engine is cool and the battery is disconnected. Remove any existing accessory drive components that will be replaced by this kit.

- Mount Main Brackets: Attach the main alternator and power steering pump relocation brackets to the engine block using the provided hardware. Ensure all bolts are finger-tight initially.

- Install Power Steering Pump: Mount your power steering pump onto its designated relocation bracket. Secure it with the appropriate hardware.

- Install Alternator: Mount your alternator onto its designated relocation bracket. The turnbuckle adjuster will connect to the alternator and the main bracket, allowing for belt tension adjustment.

- Tjek justering: Visually inspect the alignment of all pulleys. They should be in a straight line to prevent premature belt wear and noise. Use the provided shims as necessary to achieve perfect alignment, especially if using a different water pump type.

- Installer bælte: Route the serpentine belt around all pulleys. Use the turnbuckle to adjust belt tension. The belt should be taut but not excessively tight.

- Spænd alle fastgørelseselementer: Once all components are in place and aligned, progressively tighten all mounting bolts to their manufacturer's recommended torque specifications. Do not overtighten.

- Gentilslut batteri: Tilslut køretøjets batteri igen.

- Indledende opstart: Start the engine and check for proper operation, belt alignment, and any unusual noises. Monitor fluid levels if applicable.

Image: The ICT Billet LS Truck Power Steering Pump and Alternator Relocation Bracket Kit fully installed on an LS engine, showcasing the compact and relocated accessory drive system.

Image: A side perspective of the installed bracket kit, highlighting the clearance gained and the positioning of the power steering pump and alternator relative to the engine block.

Drift

Once properly installed, the ICT Billet LS Truck Power Steering Pump and Alternator Relocation Bracket Kit functions as a passive component of your engine's accessory drive system. It ensures the correct positioning and tensioning of the power steering pump and alternator, allowing these components to operate efficiently within their new relocated positions. No specific operational steps are required for the bracket kit itself beyond initial installation and periodic checks.

Opretholdelse

To ensure the longevity and proper function of your bracket kit and the associated accessories, perform the following maintenance checks periodically:

- Inspektion af fastgørelseselementer: Regularly check all mounting bolts and nuts for tightness. Vibrations can cause fasteners to loosen over time.

- Bæltespænding: Inspect the serpentine belt tension periodically. A loose belt can slip, causing accessory malfunction and noise. Adjust the turnbuckle as needed to maintain proper tension.

- Remskivejustering: Occasionally check the alignment of all pulleys. Misalignment can lead to excessive belt wear and potential component damage.

- Komponentens tilstand: Inspect the brackets for any signs of damage, cracks, or corrosion. Ensure the power steering pump and alternator are securely mounted and free from excessive play.

Fejlfinding

If you encounter issues after installation, consider the following common problems and their solutions:

| Problem | Mulig årsag | Løsning |

|---|---|---|

| Belt Squeal/Noise | Loose belt tension, misaligned pulleys, worn belt. | Adjust belt tension using the turnbuckle. Check pulley alignment. Replace worn belt. |

| Accessory Not Functioning (e.g., no power steering, no charging) | Belt slipping, accessory not properly mounted, internal accessory failure. | Check belt tension and alignment. Ensure accessory is securely bolted to the bracket. Diagnose accessory itself. |

| Clearance Issues (e.g., with headers, frame) | Incorrect crank pulley spacing, large alternator, specific vehicle chassis. | Verify crank pulley spacing. Consider a smaller alternator (105 amp). Custom fabrication may be required for extreme cases. |

| Excessive Belt Wear | Misaligned pulleys, incorrect belt type, worn pulleys. | Re-check pulley alignment using shims. Ensure correct 6-rib belt is used. Inspect pulleys for damage. |

Image: A technical drawing providing precise dimensions and clearances for the 551396LS0-3 bracket kit, useful for pre-installation planning and troubleshooting clearance issues.

Specifikationer

| Specifikation | Værdi |

|---|---|

| Modelnummer | 551396LS0-3 |

| Mærke | ICT Billet |

| Materiale | Aluminium |

| Monteringstype | Køretøjsmontering |

| Varens vægt | 5.27 pund (2.39 kg) |

| Produktmål (L x B x H) | 9.3 x 6.4 x 3.6 tommer (23.6 x 16.3 x 9.1 cm) |

| UPC | 840117202184 |

Garanti og support

For specific warranty information or technical support regarding your ICT Billet LS Truck Power Steering Pump and Alternator Relocation Bracket Kit, please contact ICT Billet directly through their official website or customer service channels. Keep your purchase receipt as proof of purchase for any warranty claims.

Kontaktoplysninger: Refer to the ICT Billet official webhjemmeside for de seneste kontaktoplysninger.