Indledning

This manual provides essential information for the installation, operation, and maintenance of your new CTS replacement carburetor. This carburetor is designed to be compatible with specific STIHL trimmer and brush cutter models. Please read these instructions carefully before proceeding with installation or use to ensure proper function and safety.

Kompatibilitet

This CTS carburetor is a direct replacement for the following models:

- STIHL Trimmers/Brush Cutters: FS160, FS220, FS280, FR220

- Replaces Zama Carburetor Models: C15-51, C1S-S3D

- Replaces Walbro Carburetor Model: WT-223

Ensure your equipment model matches one of the listed compatible models before installation.

Produkt overview

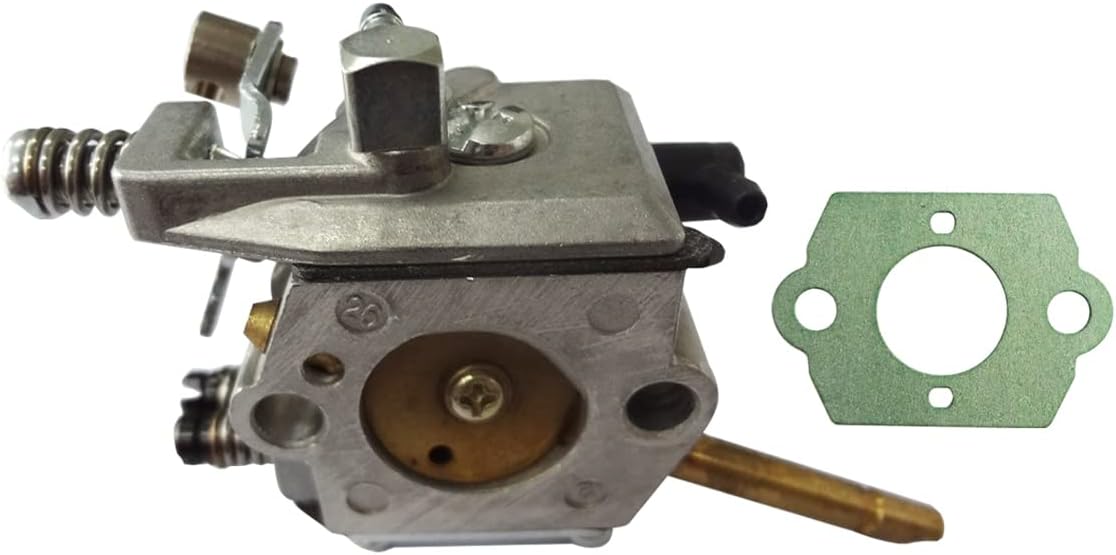

The CTS replacement carburetor is a precision component responsible for mixing air and fuel in the correct ratio for your engine. Understanding its basic components can assist with installation and maintenance.

Figur 1: Front view of the CTS replacement carburetor, showing the main body and an included gasket. The fuel inlet and adjustment screws are visible.

Figur 2: Side view of the carburetor, highlighting the throttle linkage and choke mechanism attachment points.

Opsætning og installation

Sikkerhed først: Before beginning any work on your equipment, ensure the engine is turned off and cool. Disconnect the spark plug wire to prevent accidental starting. Wear appropriate safety gear, including gloves and eye protection.

Nødvendige værktøjer:

- Skruetrækkere (Phillips og Flathead)

- Topnøglesæt

- Tang

- Brændstofledning clamps (valgfrit)

Installationstrin:

- Tøm brændstof: Carefully drain any remaining fuel from the fuel tank into an approved container.

- Remove Air Filter Assembly: Locate and remove the air filter cover and air filter element.

- Frakobl brændstofledninger: Identify and carefully disconnect the fuel lines from the old carburetor. Note their positions for correct reattachment. Use clamps if necessary to prevent fuel leakage.

- Disconnect Throttle Linkage and Choke Rod: Detach the throttle cable/linkage and choke rod from the old carburetor.

- Fjern monteringsboltene: Unscrew the bolts securing the old carburetor to the engine manifold. Carefully remove the old carburetor and any old gaskets.

- Ren monteringsoverflade: Ensure the engine manifold mounting surface is clean and free of debris.

- Install New Gaskets: Place the new gaskets (included with the carburetor) onto the manifold, ensuring correct orientation.

- Mount New Carburetor: Position the new CTS carburetor onto the manifold, aligning it with the mounting bolts. Secure it with the bolts, tightening them evenly. Do not overtighten.

- Reconnect Throttle Linkage and Choke Rod: Reattach the throttle linkage and choke rod to the new carburetor. Ensure smooth operation.

- Reconnect Fuel Lines: Reconnect the fuel lines to their correct ports on the new carburetor. Double-check for secure connections.

- Reinstall Air Filter Assembly: Replace the air filter element and air filter cover.

- Brændstofpåfyldning: Refill the fuel tank with the appropriate fuel mixture for your STIHL equipment.

After installation, it is recommended to perform initial adjustments as described in the "Operating" section.

Operating and Initial Adjustments

While this carburetor is pre-set for general use, minor adjustments may be necessary for optimal performance with your specific engine. Refer to your STIHL equipment's original instruction manual for detailed carburetor adjustment procedures.

General Adjustment Guidelines:

- High-Speed (H) Screw: Controls the fuel mixture at high engine speeds. Turning clockwise (in) leans the mixture; counter-clockwise (out) enriches it. Adjust for maximum engine speed without sputtering.

- Low-Speed (L) Screw: Controls the fuel mixture at low engine speeds and idle. Adjust for smooth idling and good acceleration.

- Idle Speed (T) Screw: Adjusts the engine's idle RPM. Turn clockwise to increase idle speed, counter-clockwise to decrease.

Vigtig: Always make small adjustments (e.g., 1/8 to 1/4 turn) and test the engine's response. Incorrect adjustments can lead to engine damage or poor performance. If you are unsure, consult a qualified service technician.

Opretholdelse

Regular maintenance helps ensure the longevity and performance of your carburetor and equipment.

- Brændstofkvalitet: Always use fresh, clean fuel mixed according to your STIHL equipment's specifications. Stale or contaminated fuel is a primary cause of carburetor issues.

- Brændstoffilter: Regularly inspect and replace the fuel filter in the fuel tank. A clogged fuel filter can restrict fuel flow to the carburetor.

- Luftfilter: Keep the air filter clean. A dirty air filter restricts airflow, causing the engine to run rich and potentially affecting carburetor performance.

- Opbevaring: Before long-term storage, drain the fuel system or use a fuel stabilizer to prevent fuel degradation and gumming in the carburetor. Run the engine until it runs out of fuel to ensure the carburetor is dry.

- Rensning: If performance issues arise, the carburetor may require cleaning. This typically involves disassembling the carburetor, cleaning passages with carburetor cleaner, and replacing gaskets. This procedure should only be performed by individuals with mechanical experience.

Fejlfinding af almindelige problemer

If you experience problems after installing the new carburetor, consider the following common issues:

| Symptom | Mulig årsag | Løsning |

|---|---|---|

| Motoren vil ikke starte | No fuel, incorrect choke position, spark plug issue, incorrect carburetor adjustment. | Check fuel level, ensure choke is set correctly, inspect spark plug, verify fuel lines are connected, adjust carburetor. |

| Motoren starter, men dør | Incorrect idle speed, fuel delivery issue, air leak. | Adjust idle speed (T screw), check fuel filter and lines, inspect for air leaks around carburetor gaskets. |

| Engine runs rough/lacks power | Incorrect fuel mixture (H or L screw), dirty air filter, old fuel. | Adjust H and L screws, clean/replace air filter, use fresh fuel. |

| Fuel leaks | Loose fuel lines, damaged gaskets, float needle issue. | Tighten fuel line connections, replace gaskets, inspect float assembly (advanced). |

If problems persist after attempting these solutions, it is recommended to seek assistance from a qualified service technician.

Specifikationer

- Produkttype: Replacement Carburetor

- Mærke: CTS

- Compatible STIHL Models: FS160, FS220, FS280, FR220

- Replaces Zama Models: C15-51, C1S-S3D

- Replaces Walbro Model: WT-223

- Produktdimensioner: 4.7 x 2 x 4 tommer

- Varens vægt: 3.7 ounce

Garanti og support

For specific warranty information or technical support regarding this CTS replacement carburetor, please refer to the seller's policies or contact the retailer where the product was purchased. Keep your proof of purchase for any warranty claims.