Produkt overview

The Scheppach HMS1070 is a versatile combined dressing and thickness planer designed for small workshops and mobile use. Its compact and lightweight design makes it ideal for various woodworking tasks. Equipped with two high-speed (HS) planer blades and a powerful 1500W motor, it ensures precise and efficient material removal. The machine features a pivoting dressing stop and a robust die-cast aluminum dressing table for accurate work. Height adjustment for thickness planing is easily managed via a rotary knob. This manual provides essential information for safe operation, setup, maintenance, and troubleshooting.

Sikkerhedsoplysninger

Always adhere to the following safety guidelines to prevent injury and ensure proper operation of your HMS1070 planer.

- Læs manualen: Before operating the machine, thoroughly read and understand all instructions and safety warnings in this manual.

- Personligt beskyttelsesudstyr (PPE): Always wear safety glasses, hearing protection, and a dust mask. Avoid loose clothing, jewelry, and long hair that could get caught in moving parts.

- Arbejdsområde: Keep the work area clean, well-lit, and free from clutter. Ensure adequate space around the machine for safe operation and material handling.

- Elektrisk sikkerhed: Ensure the power supply matches the machine's requirements. Do not operate in damp or wet conditions. Never use damaged power cords.

- Sikkert arbejdsemne: Always ensure the workpiece is properly supported and secured before feeding it into the planer.

- Klingesikkerhed: Keep hands and fingers away from the planer blades. Disconnect power before performing any adjustments, maintenance, or blade changes.

- Støvopsamling: Connect the machine to a suitable dust collection system to minimize airborne dust and maintain a clear work environment.

- Overvågning: Never leave the machine unattended while it is running. Keep children and unauthorized persons away from the operating area.

- Nødstop: Gør dig bekendt med placeringen og betjeningen af nødstopknappen.

Produktegenskaber

The HMS1070 planer offers a range of features designed for efficiency and precision:

- Combined dressing and thickness planer for the small workshop.

- Powerful 1500 W motor for effortless dressing and planing.

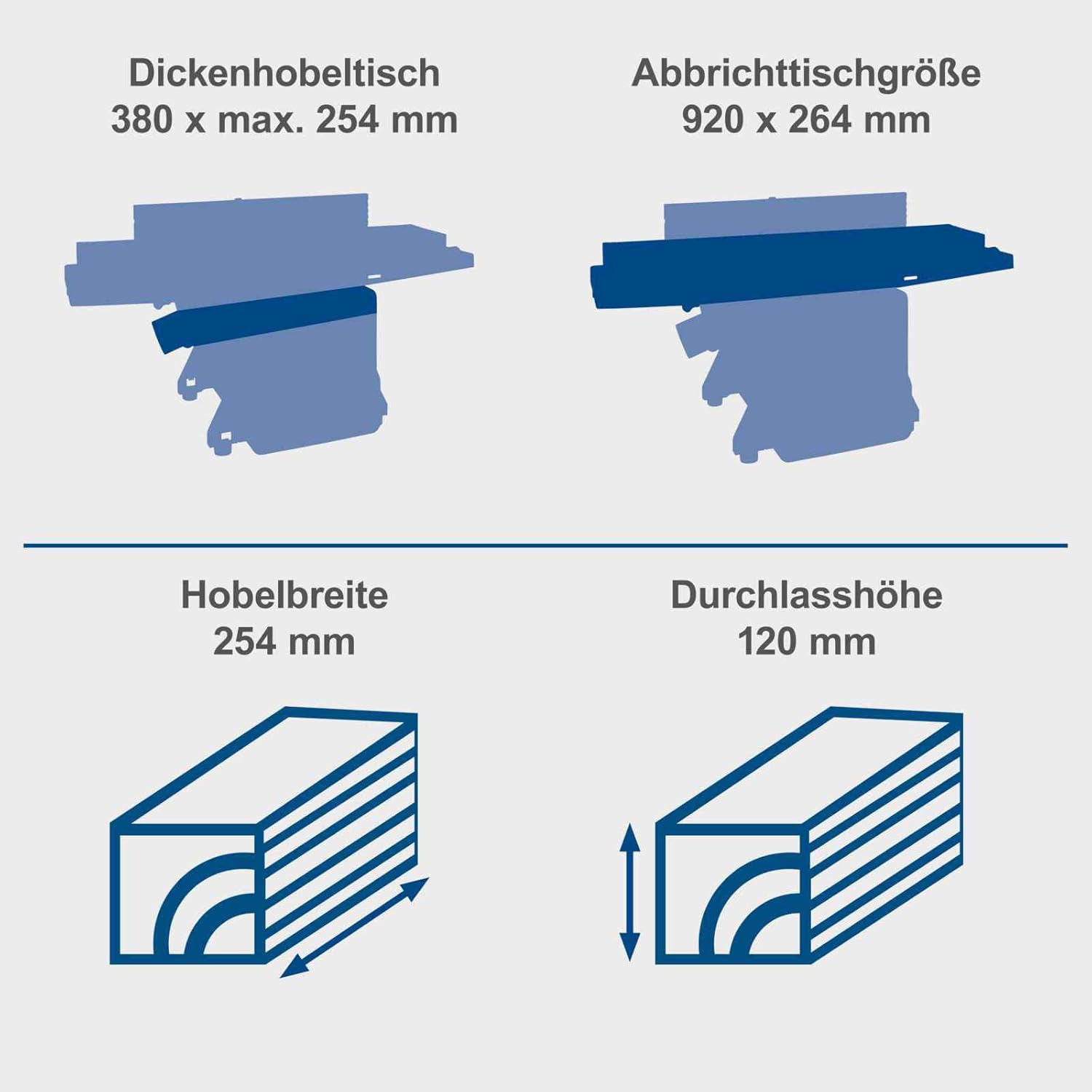

- Compact table model with a passage height and width of 120 and 254 mm.

- Two HS planer blades and a blade speed with 8500 rpm for smooth and precise planing.

- Easy height adjustment of the thickness planer via hand crank.

- Surface stop with 45° angle adjustment for exact angles from 90° to 135°.

- Vibration-absorbing rubber feet for stable stand.

Komponenter overview

Familiarize yourself with the main components of the Scheppach HMS1070 planer.

Figur 1: Samlet set view of the Scheppach HMS1070 combined planer and thicknesser, showcasing its compact design and key operational controls.

Figur 2: Demonstrates the planer in use, with a user feeding a wooden board for surface planing. This highlights the practical application and ergonomic design.

Figur 3: Illustrates key dimensions and capacities of the planer, including the thicknessing table size (380 x max. 254 mm), dressing table size (920 x 264 mm), planing width (254 mm), and passage height (120 mm).

Figur 4: Highlights core features: a powerful 1500W motor, a swiveling dressing stop adjustable from 0-45 degrees, robust construction, and a space-saving design.

Figur 5: Demonstrates the 2-in-1 functionality, showing how the machine can be easily converted between thicknessing (Dickenhobel) and dressing (Abrichtfunktion) modes.

Figur 6: Compares the HMS1070's stable, warp-resistant aluminum dressing stop with a conventional sheet metal stop, emphasizing the superior stability and precision of the HMS1070.

Figur 7: Another operational view, showing the planer actively processing wood and highlighting the dust extraction port for a cleaner workspace.

Figur 8: Giver examples of suitable applications for the HMS1070, including planing planks (Bohle), beams (Balken), and boards (Bretter), indicating its versatility for solid wood and softwood.

Opsætning og montering

Follow these steps to set up your HMS1070 planer for initial use:

- Udpakning: Carefully remove all components from the packaging. Check for any shipping damage and ensure all parts listed in the packing list are present.

- Placering: Position the planer on a stable, level workbench or stand. Ensure there is sufficient space around the machine for safe operation and material handling. The vibration-absorbing rubber feet should be in contact with the surface.

- Assembly of Dressing Stop: Attach the dressing stop to the machine according to the instructions in the detailed manual. Ensure it is securely fastened and can pivot smoothly for angle adjustments.

- Støvudsugningstilslutning: Connect a suitable dust extraction system to the machine's dust port. Proper dust collection is crucial for safety and machine performance.

- Elektrisk tilslutning: Before plugging in, ensure the machine's power switch is in the "OFF" position. Connect the power cord to a grounded electrical outlet that matches the machine's voltage requirements (240 Volts, 1500 Watts).

- Indledende inspektion: Before first use, manually check that all moving parts operate freely and that all fasteners are tight. Ensure the planer blades are correctly installed and secured.

Betjeningsvejledning

Planing (Dressing) Mode

This mode is used to flatten one face of a board and square an edge.

- Forberedelse: Ensure the machine is in planing mode. Adjust the infeed table height to control the depth of cut (maximum 2mm chip removal). Set the dressing stop to the desired angle (typically 90° for squaring edges).

- Fremføring af emnet: Place the workpiece on the infeed table with the face to be planed down. Apply even pressure and feed the workpiece smoothly and consistently across the cutterhead.

- Sikkerhed: Always keep your hands away from the cutterhead. Use push blocks or push sticks when planing short or narrow pieces.

Thicknessing Mode

This mode is used to bring a board to a uniform thickness and create parallel faces.

- Omdannelse: Convert the machine to thicknessing mode by adjusting the tables as per the detailed manual. This typically involves lifting the dressing tables out of the way.

- Højdejustering: Use the hand crank to adjust the thicknessing table to the desired final thickness. Ensure the depth of cut does not exceed the recommended maximum per pass.

- Fremføring af emnet: Place the workpiece on the thicknessing table and feed it into the machine. The automatic feed rollers will pull the wood through.

- Flere gennemløb: For significant material removal, make several shallow passes rather than one deep pass to achieve a smoother finish and reduce strain on the motor.

Opretholdelse

Regelmæssig vedligeholdelse sikrer din høvls levetid og optimale ydeevne.

- Rensning: After each use, disconnect the power and clean the machine thoroughly. Remove all wood chips and dust from the tables, cutterhead area, and dust port. Use a brush or compressed air.

- Inspektion og udskiftning af knive: Regularly inspect the HS planer blades for sharpness and damage. Dull or chipped blades can lead to poor finish and increased motor strain. Replace blades as a set to maintain balance. Refer to the detailed manual for blade replacement procedures.

- Smøring: Periodically lubricate moving parts, such as the height adjustment screws and feed rollers, with a suitable lubricant as recommended in the full manual.

- Bordvoksning: Apply a thin coat of paste wax to the planer tables to reduce friction and prevent rust.

- Fastgørelseskontrol: Periodically check all nuts, bolts, and screws for tightness and tighten if necessary.

Fejlfinding

This section addresses common issues you might encounter with your HMS1070 planer.

| Problem | Mulig årsag | Løsning |

|---|---|---|

| Maskinen starter ikke | No power supply; Emergency stop engaged; Thermal overload tripped | Check power connection and circuit breaker; Release emergency stop; Allow motor to cool down and reset thermal overload. |

| Rough or uneven finish | Dull or damaged blades; Incorrect depth of cut; Uneven feed rate; Wood grain issues | Replace blades; Reduce depth of cut; Maintain consistent feed rate; Consider grain direction. |

| Snipe at ends of workpiece | Lack of proper support for workpiece; Excessive depth of cut | Use infeed/outfeed supports; Reduce depth of cut; Make lighter passes. |

| Overdreven vibration eller støj | Loose components; Unbalanced blades; Machine not stable on surface | Check and tighten all fasteners; Ensure blades are correctly installed and balanced; Place machine on a firm, level surface. |

| Wood not feeding through | Feed rollers clogged or worn; Excessive depth of cut; Workpiece too large | Clean feed rollers; Reduce depth of cut; Ensure workpiece dimensions are within machine capacity. |

Tekniske specifikationer

Key technical data for the Scheppach HMS1070 Planer & Thickness Planer:

| Specifikation | Værdi |

|---|---|

| Mærke | Scheppach |

| Modelnummer | HMS1070 |

| Strømkilde | Elektrisk med ledning |

| Motorkraft | 1500 watt |

| Voltage | 240 volt |

| Maksimal rotationshastighed | 8500 RPM |

| Cutting Depth (Max Chip Removal) | 2 millimeter |

| Høvlebredde (maks.) | 254 mm (approx. 4.68 Inches) |

| Passage Height (Thicknessing) | 120 mm |

| Produktmål (L x B x H) | 37.99 cm x 19.49 cm x 19.02 cm |

| Varens vægt | 26 kilogram (ca. 57.2 pund) |

| Materiale | Legeret stål |

| Farve | Blå |

Garanti og support

Scheppach provides support for its products. For specific warranty details, please refer to the documentation included with your purchase or contact Scheppach customer service directly.

Extended protection plans may be available for your HMS1070 planer:

- 3-årig beskyttelsesplan: Offers extended coverage for your product.

- 4-årig beskyttelsesplan: Provides even longer-term protection.

- Fuld beskyttelse: A comprehensive plan covering eligible past and future purchases.

For technical assistance, spare parts, or service inquiries, please contact the manufacturer or your authorized dealer.