Indledning

This manual provides essential information for the safe and effective installation, operation, and maintenance of your Red Hat 1/4" NPT 3-Way Solenoid Valve. This valve is designed for precise control of air/inert gas, light oil, and water flow in various industrial and scientific applications. Please read this manual thoroughly before installation and operation.

Sikkerhedsoplysninger

Overhold altid følgende sikkerhedsforanstaltninger for at forhindre personskade eller beskadigelse af udstyret:

- Sørg for, at al strøm er afbrudt før installation, vedligeholdelse eller fejlfinding.

- Verify that the operating pressure and temperature of the system do not exceed the valve's specified limits.

- Brug passende personlige værnemidler (PPE) under installation og vedligeholdelse.

- Installation should be performed by qualified personnel in accordance with local codes and regulations.

- Do not modify the valve or its components.

Produkt overview

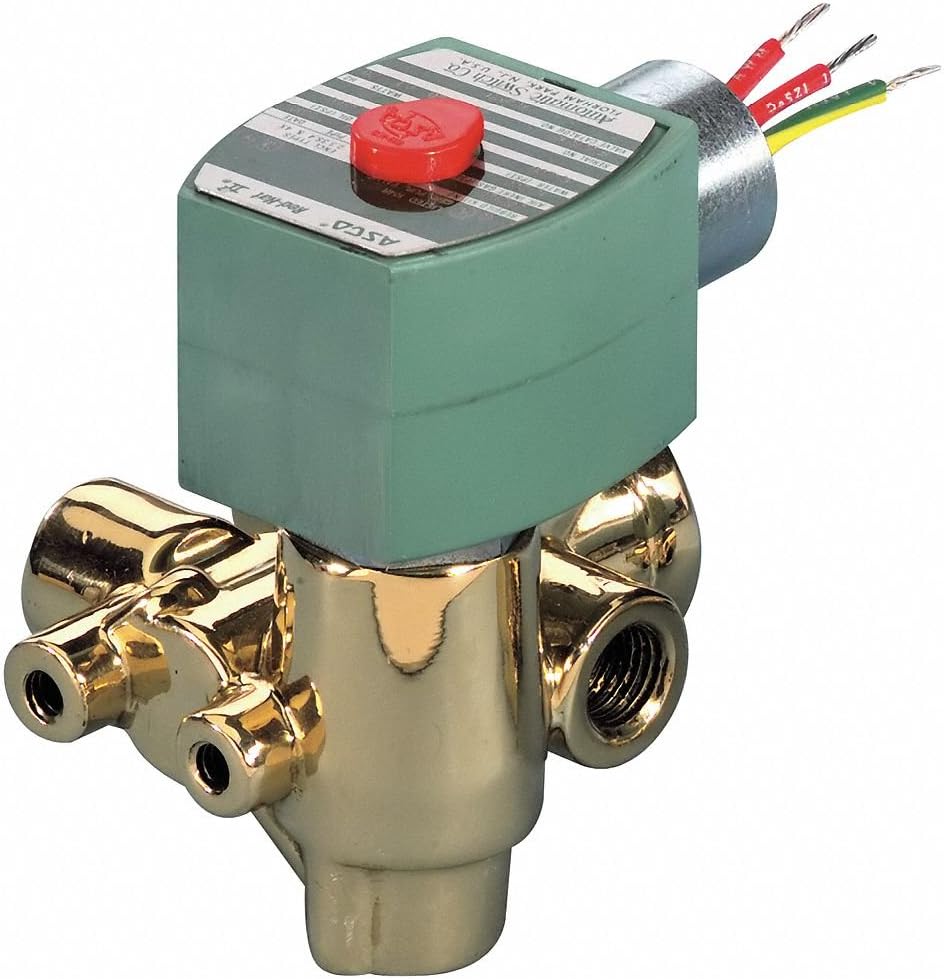

The Red Hat 1/4" NPT 3-Way Solenoid Valve features a durable brass body and is designed for normally closed operation. It includes a solenoid coil for electrical actuation and NPT threaded ports for connection to piping systems.

Figure 1: Red Hat 1/4" NPT 3-Way Solenoid Valve. This image shows the brass valve body with three threaded ports and the green solenoid coil assembly on top, featuring a red manual override button and electrical wiring.

Specifikationer

| Attribut | Værdi |

|---|---|

| Kropsmateriale | Messing |

| Medier | Air/Inert Gas, Light Oil, Water |

| Konfiguration | 3-Way/2-Position, Normally Closed |

| Rørstørrelse | 1/4 In. NPT |

| åbningsdiameter | 9/32 in. |

| Coefficient of Volume (Cv) | 0.80 |

| Min. Operating Pressure Differential | 10 psi |

| Max. Operating Pressure Differential (Air/Inert Gas) | 200 psi |

| Max. Operating Pressure Differential (Light Oil) | 200 psi |

| Max. Operating Pressure Differential (Water) | 200 psi |

| Coil Insulation Class | H |

| NEMA Rating | 3, 3S, 4, 4X, 6, 6P, 7, 9 |

| Maks. Væsketemperatur | 120 grader F |

| Voltage | 125VDC |

| Fabrikant | REDHAT |

| Varenummer | EFHC8321G001125/DCDD |

| UPC | 696504961345 |

Opsætning og installation

Følg disse trin for korrekt installation:

- Systemforberedelse: Ensure the system is depressurized and drained before installation. Clean all piping and fittings to prevent debris from entering the valve.

- Montering: Mount the valve in a location that allows for easy access for maintenance and inspection. The valve can be mounted in any position without affecting operation, but mounting with the solenoid upright is generally preferred to extend life.

- Rørforbindelser: Connect the piping to the valve's NPT ports. Use a suitable thread sealant (e.g., PTFE tape or pipe dope) on the male threads. Do not overtighten connections, as this can damage the valve body. Ensure the flow direction matches the valve's design (if applicable, though for 3-way, ports are typically marked).

- Elektriske ledninger: Connect the 125VDC power supply to the solenoid coil terminals. Ensure wiring conforms to all local electrical codes. Verify the voltage matches the coil's rating (125VDC).

- Lækagetjek: After installation, slowly pressurize the system and check all connections for leaks using an appropriate leak detection method.

Betjeningsvejledning

The Red Hat 3-Way Solenoid Valve is a normally closed (NC) valve. This means:

- De-energized State: When no power is applied to the solenoid coil, the valve is in its normal (closed) state. In a 3-way normally closed configuration, this typically means one port is connected to a common port, and the third port is blocked or vented. For this specific valve, it means the inlet port is closed, and the exhaust port is open to the common port.

- Energized State: When 125VDC power is applied to the solenoid coil, the valve shifts to its open state. The inlet port opens to the common port, and the exhaust port is closed.

To operate, simply apply or remove the specified DC voltage to the solenoid coil as required by your control system.

Opretholdelse

Regular maintenance ensures optimal performance and extends the life of your solenoid valve. Always depressurize and disconnect power before performing any maintenance.

- Periodisk eftersyn: Regularly inspect the valve for signs of leaks, corrosion, or damage to the coil.

- Rensning: If the valve is exposed to dirty media, periodic cleaning of internal components may be necessary. Consult a qualified technician for disassembly and cleaning procedures.

- Udskiftning af pakning: Over time, seals may wear out. Replacement kits are typically available from the manufacturer.

- Coil Check: Ensure the coil is free from excessive heat buildup or physical damage.

Fejlfinding

| Problem | Mulig årsag | Løsning |

|---|---|---|

| Valve does not open/close | Ingen strøm til spolen; Forkert lydstyrketage; Damaged coil; Obstruction in valve; Low pressure differential | Check power supply and wiring; Verify voltage matches coil rating; Replace coil; Clean valve internals; Ensure minimum pressure differential is met |

| Valve leaks externally | Loose connections; Damaged body or seals | Tighten connections (do not overtighten); Inspect and replace damaged seals or valve body |

| Valve leaks internally (passing fluid) | Worn seals; Debris lodged in valve seat | Replace internal seals; Disassemble and clean valve internals |

| Excessive coil heat | Forkert voltage; Continuous duty cycle not intended for coil; High ambient temperature | Bekræft korrekt voltage; Ensure coil is rated for continuous duty if required; Improve ventilation around valve |

Garanti og support

For information regarding warranty coverage, technical support, or replacement parts, please contact Red Hat customer service or refer to the official Red Hat webwebsted. Hav din købskvittering og produktets modelnummer ved hånden, når du kontakter support.