Indledning

The Scheppach Tiger 2000S is a professional wet grinding system designed for sharpening and honing various tools, ideal for both hobbyists and professionals. This system ensures precise and razor-sharp results by utilizing a continuously water-cooled whetstone, preventing overheating and maintaining tool hardness. Its low-speed induction motor provides quiet and low-vibration operation, making it a reliable choice for maintaining the sharpness of your valuable tools.

This manual provides detailed instructions for the safe and effective use, setup, operation, and maintenance of your Tiger 2000S sharpening system.

Sikkerhedsinstruktioner

Always read and understand all safety warnings and instructions before operating the machine.

- Sørg for, at maskinen er placeret på en stabil, plan overflade.

- Always wear appropriate personal protective equipment, including safety glasses, during operation.

- Keep hands and fingers clear of moving parts, especially the grinding wheel and honing wheel.

- Brug ikke maskinen i våde eller dråbeformede områder.amp conditions, except for the water bath as intended.

- Disconnect the power supply before performing any maintenance, adjustments, or when the machine is not in use.

- Do not force the tool against the grinding wheel; allow the machine to work at its own pace.

- Hold børn og uautoriserede personer væk fra driftsområdet.

- Undersøg regelmæssigt netledningen for skader. Må ikke anvendes, hvis den er beskadiget.

Pakkens indhold

Upon unpacking, ensure all components are present and undamaged. The standard package for the Tiger 2000S includes:

- Tiger 2000S Wet Grinding System unit

- Precious Corundum Whetstone (200 mm diameter, 40 mm thickness, K 220 grit)

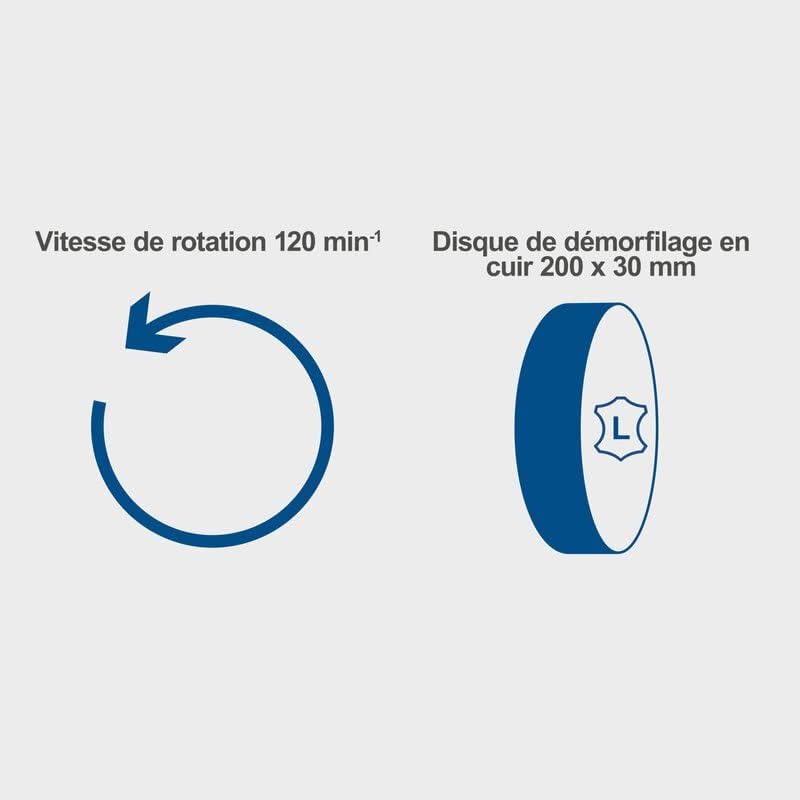

- Leather Honing Disc (200 x 30 mm)

- Universal Grinding Device 70

- Vinkelmåler

- Honing Compound

Image: The Scheppach Tiger 2000S sharpening system, showing the main unit with the grinding wheel and leather honing wheel, along with the universal grinding device, angle gauge, and honing compound.

Billede: Detaljeret view of the included accessories: the universal grinding device for precise tool holding, the honing compound for polishing, and the angle gauge for setting the correct sharpening angle.

Opsætning

- Udpakning: Fjern forsigtigt alle komponenter fra emballagen. Gem emballagen til senere opbevaring eller transport.

- Placering: Position the Tiger 2000S on a stable, flat, and non-slip surface. Ensure adequate space around the machine for safe operation.

- Vandtank: Fill the shatterproof water tank with clean water. The water level should be sufficient to immerse the lower part of the grinding wheel during operation. This ensures continuous cooling and prevents annealing of the tool.

- Grinding Wheel Installation: Ensure the corundum whetstone is securely mounted. While the description states it's part of standard equipment, if it needs assembly, follow the specific instructions in the product's physical manual for mounting the stone and the support bar.

- Leather Honing Disc: Verify the leather honing disc is properly attached and free from obstructions. The leather is easily removable and replaceable if needed.

- Strømtilslutning: Connect the power cord to a suitable 230V (AC) power outlet.

Betjeningsvejledning

The Tiger 2000S wet grinding system is designed for precise sharpening and honing. Follow these steps for optimal results:

1. Klargøring af værktøjet

- Rengør værktøjet: Ensure the tool to be sharpened is clean and free of debris.

- Use the Universal Grinding Device 70: For most tools, especially those with straight edges like chisels or plane irons, secure the tool in the universal grinding device 70. This device helps maintain the correct angle and prevents slipping.

- Set the Angle with the Angle Gauge: Use the included angle gauge to determine and set the correct grinding angle for your specific tool. This is crucial for achieving a sharp and lasting edge.

Image: A user demonstrating the sharpening process on the Tiger 2000S, using the universal grinding device to hold a chisel at the correct angle against the wet grinding wheel.

2. Sharpening Process (Grinding)

- Start maskinen: Turn on the Tiger 2000S. The grinding wheel will rotate at a low speed (120 min-1) in the water bath.

- Apply Tool to Grinding Wheel: Gently bring the tool, held by the universal grinding device, into contact with the rotating wet grinding wheel. Apply consistent, light pressure.

- Bevar vinkel: Continuously monitor and maintain the set grinding angle. The water cooling prevents the tool from overheating and losing its hardness.

- Grind Until Burr Forms: Continue grinding until a small burr (wire edge) forms along the opposite edge of the sharpened surface. This indicates that the two bevels have met.

Billede: Visuelt eksempelamples of various tools suitable for sharpening with the Tiger 2000S, including turning tools, scissors, axes, and knives, highlighting the system's versatility.

3. Honing Process (Deburring and Polishing)

- Apply Honing Compound: Apply a small amount of the included honing compound to the leather honing disc.

- Remove Burr: With the machine still running, gently apply the burr side of the sharpened tool to the rotating leather honing disc. This will remove the burr and refine the edge.

- Polish the Edge: Continue to lightly hone the edge on the leather disc until it is polished and razor-sharp. The leather disc ensures a perfect cutting edge.

Image: A user demonstrating the deburring process on the Tiger 2000S, using the leather honing disc to remove the burr from an axe blade and achieve a perfect cutting edge.

Opretholdelse

Regular maintenance ensures the longevity and optimal performance of your Tiger 2000S sharpening system.

- Vandtank: Regularly empty and clean the water tank to prevent buildup of grinding residue. Use fresh water for each sharpening session.

- Slibeskive: Over time, the grinding wheel may become uneven or glazed. Use a dressing stone (not included, but recommended for maintenance) to true and clean the surface of the whetstone.

- Leather Honing Disc: If the leather disc becomes worn or saturated with honing compound, it can be easily removed and replaced. Ensure it remains clean for effective polishing.

- Generel rengøring: Tør maskinen af med adamp cloth after use to remove any dust or grinding particles. Do not use harsh chemicals.

- Opbevaring: Store the machine in a dry, clean place, away from direct sunlight and extreme temperatures.

Fejlfinding

| Problem | Mulig årsag | Løsning |

|---|---|---|

| Maskinen starter ikke. | No power supply; power switch off; damaged cord. | Check power connection; ensure switch is ON; inspect power cord for damage. |

| Grinding wheel not rotating smoothly. | Insufficient water in tank; wheel not properly seated; motor issue. | Add water to the tank; check wheel mounting; contact service if motor issue suspected. |

| Tools not getting sharp. | Incorrect grinding angle; worn grinding wheel; insufficient honing. | Re-check angle with gauge; dress or replace grinding wheel; ensure proper honing on leather disc. |

| Overdreven vibration eller støj. | Unstable surface; unbalanced grinding wheel; loose components. | Place on stable surface; true the grinding wheel; check all fasteners. |

Specifikationer

| Feature | Detalje |

|---|---|

| Mærke | Scheppach |

| Model | 1 (Tiger 2000S) |

| Produktdimensioner | 13.7 cm L x 11.22 cm B x 10.83 cm H |

| Strømkilde | Elektrisk med ledning |

| Voltage | 230 volt (AC) |

| Wattage | 120 watt |

| Grinding Wheel Material | Precious Corundum with Aluminium Oxide |

| Grinding Wheel Dimensions | 200 mm diameter, 40 mm tykkelse |

| Kornnummer | K 220 (Extra Fine) |

| Maksimal rotationshastighed | 120 RPM (120 min-1) |

| Honing Disc Material | Læder |

| Honing Disc Dimensions | 200 mm diameter, 30 mm tykkelse |

| Varens vægt | 8.5 kilo (18.7 pund) |

Image: Technical diagram illustrating the dimensions and grit of the corundum grinding wheel: 200 mm diameter, 40 mm width, 220K grit, and 12 mm bore.

Image: Technical diagram indicating the rotation speed of 120 revolutions per minute and the dimensions of the leather deburring disc: 200 mm diameter by 30 mm thickness.

Garanti og support

Scheppach products are manufactured to high quality standards. For information regarding warranty coverage, terms, and conditions, please refer to the warranty card included with your product or visit the official Scheppach webwebstedet. Behold din købskvittering som købsbevis.

For technical support, spare parts, or service inquiries, please contact Scheppach customer service. Contact details can typically be found on the manufacturer's webwebsted eller i produktemballagen.

Online ressourcer: For additional tips, tutorials, and product information, you may visit the official Scheppach website or authorized dealer webwebsteder.