1. Introduktion

This manual provides essential information for the proper installation, operation, and maintenance of the Timken A2037 Tapered Roller Bearing Cone. Adhering to these instructions will ensure optimal performance and longevity of the bearing.

The Timken A2037 is a single tapered roller bearing cone designed to be paired with a compatible cup (outer ring, sold separately) to form a complete bearing unit. This assembly is engineered to support both radial and axial loads in various industrial and automotive applications.

2. Produktet er slutview

The Timken A2037 Tapered Roller Bearing Cone features a high-alloy steel construction for durability and resistance to deformation under heavy loads. Its stamped steel cage maintains precise roller spacing, contributing to reduced friction, vibration, and noise during operation. The open design facilitates lubrication and allows for accurate adjustments during installation.

Figur 1: Timken A2037 Tapered Roller Bearing Cone. This image shows the bearing cone with its rollers and inner ring.

Nøglefunktioner:

- Single cone (inner ring) for assembly with compatible outer rings (cups).

- Designet til at understøtte både radiale og aksiale belastninger.

- Driftstemperaturområde: -54°C til 120°C (-65°F til 250°F).

- Stamped steel cage for precise roller spacing, reducing friction and noise.

- Open configuration for easy lubrication and adjustment.

3. Opsætning og installation

Proper installation is crucial for the performance and lifespan of the tapered roller bearing. This bearing cone must be paired with a suitable cup (outer ring) to form a complete bearing unit. Consult your equipment's service manual for specific installation procedures and torque specifications.

3.1 Components Required:

- Timken A2037 Tapered Roller Bearing Cone (included).

- Compatible Tapered Roller Bearing Cup (outer ring, sold separately).

- Appropriate lubricant (e.g., grease, as specified by equipment manufacturer).

- Installation tools (e.g., bearing press, specialized drivers, torque wrench).

3.2 Kontroller før installation:

- Inspect the bearing cone and cup for any signs of damage, corrosion, or manufacturing defects. Do not install damaged components.

- Ensure all mating surfaces on the shaft and housing are clean, smooth, and free from burrs or foreign particles.

- Verify that the shaft and housing dimensions are within specified tolerances for the A2037 bearing.

3.3 Installationsprocedure:

- Apply a thin, even coat of compatible lubricant to the bearing cone and cup surfaces.

- Press the bearing cone onto the shaft using a bearing press or appropriate driver. Ensure even pressure is applied to the inner ring face to avoid damage. Never strike the rollers or cage directly.

- Press the bearing cup into the housing bore, ensuring it is seated squarely and fully against the shoulder.

- Assemble the shaft with the cone into the housing with the cup.

- Adjust the bearing setting (preload or end play) according to the equipment manufacturer's specifications. This typically involves tightening a retaining nut to a specific torque value while rotating the shaft to seat the rollers.

- Perform a final check to ensure smooth rotation and proper seating.

Figur 2: Front view technical drawing of the Timken A2037 Tapered Roller Bearing Cone, showing internal dimensions and structure.

Figur 3: Side view technical drawing of the Timken A2037 Tapered Roller Bearing Cone, illustrating its profile and width.

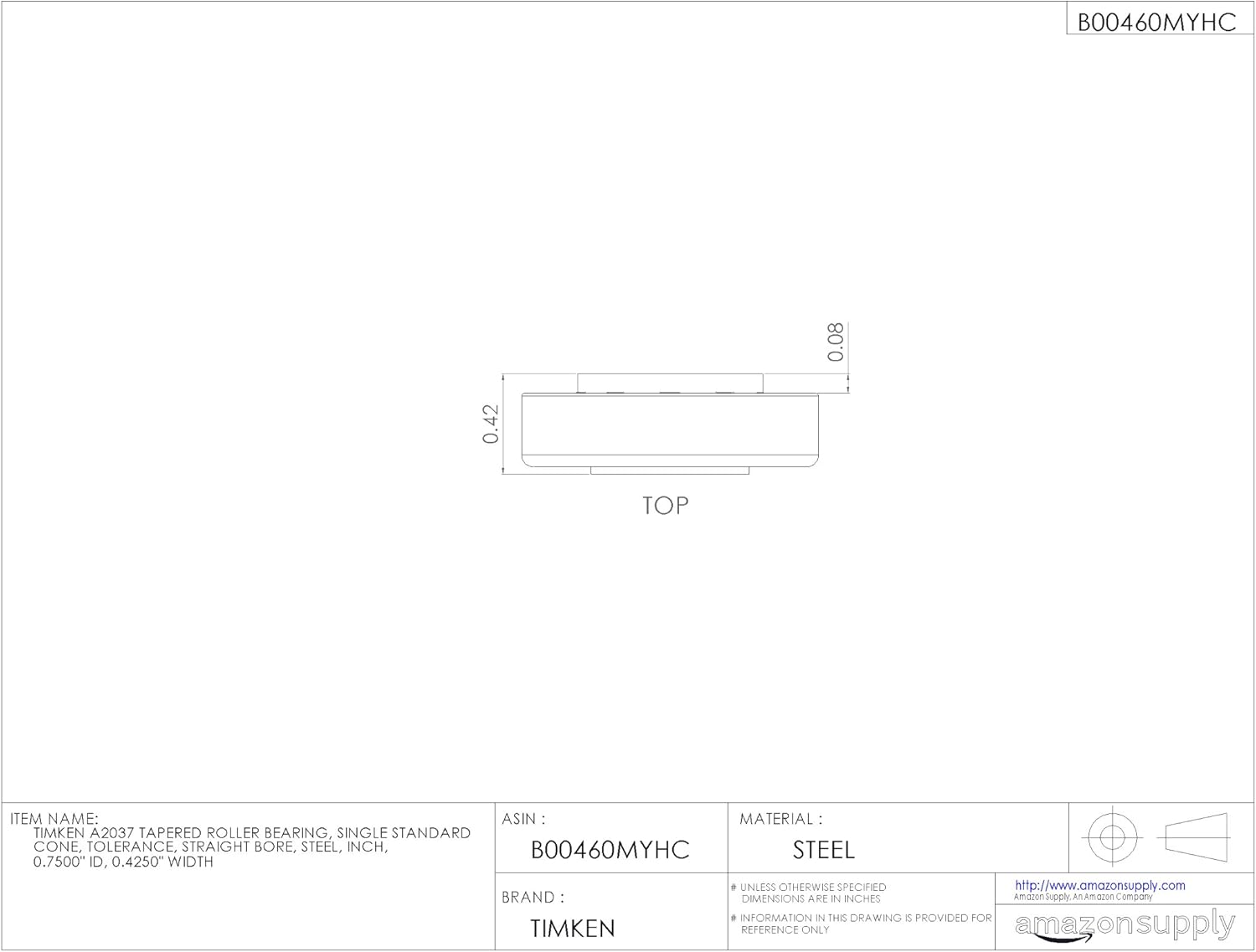

Figur 4: Top view technical drawing of the Timken A2037 Tapered Roller Bearing Cone, showing its diameter and overall dimensions.

4. Driftsvejledninger

Once installed, the Timken A2037 bearing cone, as part of a complete tapered roller bearing, is designed for reliable operation under specified conditions. Proper operating practices contribute to extended bearing life.

- Belastningskapacitet: This bearing supports both radial and axial loads. Ensure that the applied loads do not exceed the bearing's rated capacity.

- Hastighed: Operate within the recommended speed limits for tapered roller bearings in your specific application. Excessive speeds can lead to overheating and premature failure.

- Temperatur: The bearing is designed for operating temperatures between -54°C and 120°C (-65°F and 250°F). Monitor operating temperatures to prevent overheating, which can degrade lubricant and bearing materials.

- Smøring: Maintain adequate lubrication as per the equipment manufacturer's schedule. The open configuration of this bearing allows for lubrication applied in place.

5. Vedligeholdelse

Regular maintenance is essential for maximizing the service life of the Timken A2037 Tapered Roller Bearing Cone.

5.1 Smøring:

Tapered roller bearings require periodic relubrication. The frequency and type of lubricant depend on the application, operating conditions, and environment. Refer to your equipment's maintenance schedule for specific lubrication requirements. Use only compatible lubricants (e.g., grease) as recommended.

5.2 Eftersyn:

Periodically inspect the bearing and surrounding components for:

- Unusual noise or vibration during operation.

- Signs of lubricant leakage or contamination.

- Overdreven varmeudvikling.

- Visible wear or damage to the bearing surfaces, cage, or rollers.

Løs eventuelle problemer omgående for at forhindre yderligere skade.

5.3 Replacement:

Replace the bearing cone and cup as a set if any signs of wear, pitting, spalling, or other damage are observed. Do not replace only one component of a tapered roller bearing set, as this can lead to premature failure of the new component.

6. Fejlfinding

This section provides general guidance for common issues related to tapered roller bearings. For specific diagnostic procedures, consult your equipment's service manual.

| Symptom | Mulig årsag | Handling |

|---|---|---|

| Overdreven støj/vibration |

|

|

| Overophedning |

|

|

| Premature Wear/Failure |

|

|

7. Specifikationer

The following specifications apply to the Timken A2037 Tapered Roller Bearing Cone:

| Attribut | Værdi |

|---|---|

| Mærke | TIMKEN |

| Modelnummer | A2037 |

| Leje Type | Tapered Roller Bearing Cone |

| Materiale | Legeret stål |

| Varens vægt | 1.28 ounces (ca. 0.08 pund) |

| Produktmål (L x B x H) | 3 x 3 x 1 tommer |

| Driftstemperaturområde | -54°C til 120°C (-65°F til 250°F) |

| Kompatibelt smøremiddel | Grease (as specified by application) |

| Udvendig finish | Maskinbearbejdet |

| UPC | 053893108667 |

Opfyldte standarder:

- ISO 355 (Tapered roller bearings—Boundary dimensions and series designations)

- ABMA standard 19.2 (Inch part numbering system)

- ISO 492 (Width tolerance standards)

- ISO 720 (Tapered roller bearing naming conventions)

- ABEC (Specification Met)

8. Garanti og support

For warranty information and technical support regarding your Timken A2037 Tapered Roller Bearing Cone, please contact Timken customer service or visit the official Timken webwebsted. Gem din købsbevis til garantikrav.

Fabrikant: Timken Company

Webwebsted: www.timken.com