1. Introduktion

This manual provides essential information for the safe and efficient operation of your DC Brushless Gear Motor. This motor is designed for various applications requiring precise and reliable rotational power, featuring a compact design and robust performance. Please read this manual thoroughly before installation and operation to ensure proper use and longevity of the product.

2. Sikkerhedsoplysninger

Always observe the following safety precautions to prevent injury or damage to the motor or connected equipment:

- Strømforsyning: Sørg for, at strømforsyningen voltage and current match the motor's specifications (12V or 24V DC). Incorrect voltage kan beskadige motoren.

- Ledningsføring: Connect wiring correctly according to the provided diagrams. Incorrect wiring can lead to malfunction or damage.

- Overbelastningsbeskyttelse: Do not exceed the motor's rated continuous current. Implement appropriate overload protection in your system if necessary.

- Varmeafledning: Ensure adequate ventilation around the motor to prevent overheating, especially during prolonged operation or high loads.

- Mekaniske farer: Keep hands, clothing, and other objects clear of rotating parts during operation.

- Miljø: Operate the motor in a clean, dry environment, free from excessive dust, moisture, and corrosive gases.

- Demontering: Do not attempt to disassemble or modify the motor. This will void the warranty and may cause damage or injury.

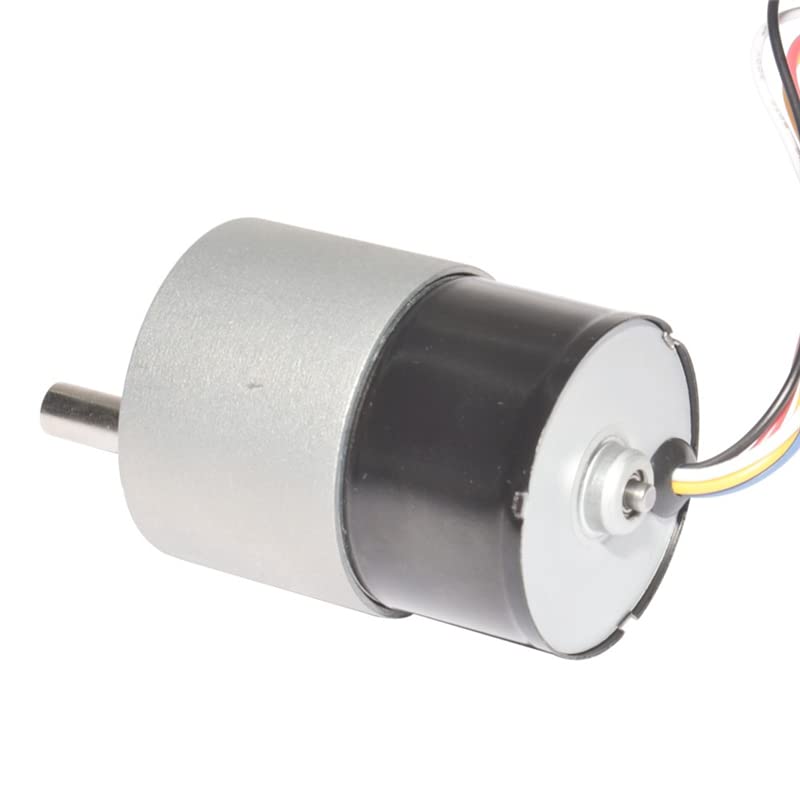

3. Produktet er slutview og komponenter

The DC Brushless Gear Motor is a robust power unit designed for various industrial and hobby applications. It integrates a brushless DC motor with a reduction gearbox to provide high torque at lower speeds.

Nøglefunktioner:

- Brushless DC design for long lifespan and high efficiency.

- Integrated gear reduction for increased torque output.

- Available in 12V and 24V configurations.

- Compact 37mm diameter.

- Drip-proof protection feature.

- Continuous Current(A): 0.08 - 0.41A (depending on model and load).

Motor Views:

4. Opsætning og installation

Proper installation is crucial for the motor's performance and longevity. Follow these general guidelines:

- Montering: Securely mount the motor using the provided mounting holes on the front flange. Ensure the mounting surface is flat and rigid to prevent vibration.

- Akselforbindelse: Connect the load to the output shaft using a suitable coupling. Ensure the coupling is properly aligned to avoid excessive radial or axial loads on the shaft.

- Ledningsføring:

- Identify the power input wires (typically red for positive, black for negative).

- Connect these to a stable DC power supply matching the motor's voltage (12V eller 24V).

- For brushless motors, additional wires are typically for Hall sensors and control signals (e.g., speed control, direction). Refer to your specific motor's wiring diagram or controller manual for precise connections.

- Sørg for, at alle forbindelser er sikre og isolerede for at forhindre kortslutninger.

- Controllerintegration: If using an external motor controller (ESC), connect the motor's phase wires and Hall sensor wires to the controller as per the controller's instructions.

- Indledende test: Before full operation, perform a low-power test to verify correct rotation and functionality.

5. Betjeningsvejledning

Once installed and wired correctly, the motor can be operated. The specific control method depends on your application and chosen motor controller.

- Tænd: Apply the specified DC voltage to the motor's power input. If using a controller, power on the controller first.

- Hastighedskontrol: Adjust the motor speed using your connected motor controller or power supply. Brushless DC motors typically use Pulse Width Modulation (PWM) for speed control.

- Retningskontrol: The direction of rotation can usually be reversed by swapping two of the three phase wires (for sensorless motors) or by a specific signal from your motor controller (for sensored motors). Consult your controller's manual.

- Overvågning: During operation, monitor the motor for unusual noises, excessive heat, or vibrations. Discontinue use if any abnormal conditions are observed.

- Stopper: Reduce the power input or signal to the controller to stop the motor.

6. Vedligeholdelse

The DC Brushless Gear Motor is designed for low maintenance. However, periodic checks can extend its lifespan:

- Rensning: Keep the motor clean and free from dust, dirt, and debris. Use a soft, dry cloth. Do not use solvents or abrasive cleaners.

- Inspektion: Periodically inspect the motor for any signs of wear, damage, or loose connections. Check the output shaft for excessive play.

- Smøring: The gearbox is typically sealed and pre-lubricated for life. Do not attempt to lubricate unless specifically instructed by the manufacturer.

- Ventilation: Ensure that ventilation openings (if any) are not obstructed.

7. Fejlfinding

Hvis du støder på problemer med din motor, kan du se følgende almindelige problemer og løsninger:

| Problem | Mulig årsag | Løsning |

|---|---|---|

| Motoren kører ikke | No power supply; Incorrect wiring; Faulty controller; Motor damage. | Kontroller strømtilslutninger og volumentage; Verify wiring against diagram; Test controller; Contact support if motor is damaged. |

| Motor runs erratically or vibrates excessively | Loose connections; Improper mounting; Overload; Damaged bearings/gears. | Secure all connections; Re-mount motor properly; Reduce load; Contact support if internal damage is suspected. |

| Motoren overophedes | Excessive load; Insufficient ventilation; Prolonged operation at high current. | Reduce load; Ensure proper airflow around motor; Allow motor to cool down periodically. |

| Reduced speed or torque | Lav voltage; Excessive load; Worn gears. | Bekræft strømforsyningen voltage; Reduce load; Contact support if gears are suspected to be worn. |

8. Specifikationer

| Attribut | Værdi |

|---|---|

| Modelnummer | 37GB-BL3625 |

| Type | Gear Motor (Brushless DC) |

| Voltage Valgmuligheder | 12V, 24V DC |

| Diameter | 37 mm |

| Continuous Current (A) | 0.08 - 0.41A |

| Beskyt funktion | Dryp-bevis |

| Motorvægt | 320 g |

| Fabrikant | Nastyaer |

| Dato først tilgængelig | 6. juni 2024 |

Note: Specific RPM values (10/20/35/65/100/150/200/300/600/1000 RPM) depend on the specific variant purchased. The current model is specified as 600rpm / 12V.

9. Garanti og support

This product is manufactured by Nastyaer. For warranty information, technical support, or service inquiries, please contact the seller or manufacturer directly. Please have your product model number (37GB-BL3625) and purchase details ready when contacting support.

For general inquiries, refer to the product listing on Amazon.com or contact Generic customer service.